SCR ELEKTRONIKS is working with appliance manufacturers and conformity assessment agencies in India in this domain. We strive to provide affordable and accurate test measurement instruments for R&D and routine testing - in the common interests of building energy efficient products with environmentally friendly process of manufacturing.

We follow the developments with the Bureau of Energy Efficiency very closely so it’s easy for you to choose the right instrument based on your products.

Government aims at energy efficiency. Domestic appliances such as Induction cook-tops, water heaters, Air conditioners, Air coolers and gas heaters need to be designed for maximum efficiency. This is plain good for the environment and saves on energy bills. Like in many other nations, India's Bureau of Energy Efficiency plans to enforce standards to force manufacturers to adhere to higher energy efficiency levels. SCR ELEKTRONIKS has been a leader in India since 1975 when it comes to electrical safety and performance test equipment. We created this system to test counter-top induction hobs in accordance with Schedule 26 (dt. 22 September 2020) of the BEE draft (Please contact us for complete catalogue of similar equipment)

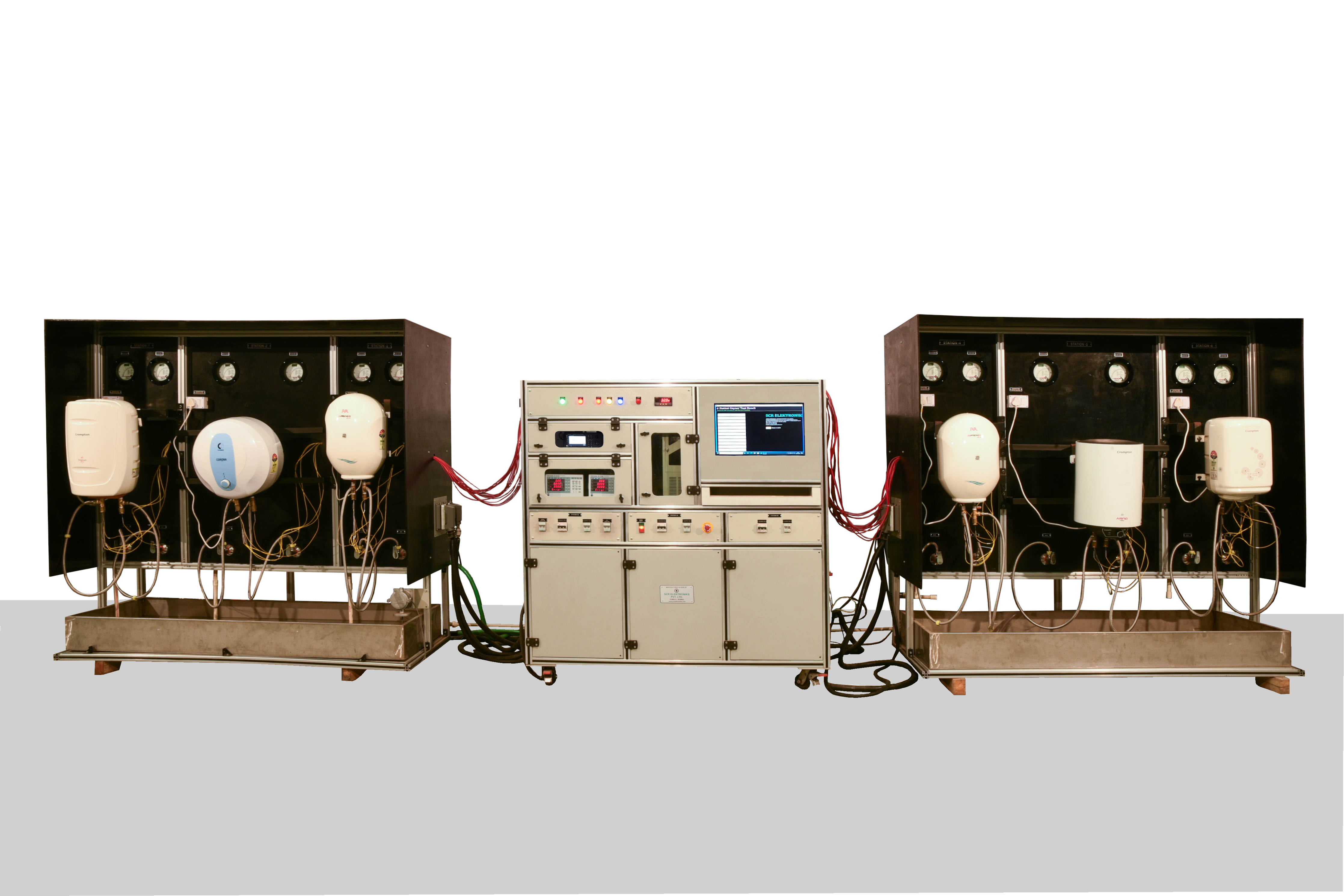

The testing setup will mainly comprise of :

1. Stabilised Power Supply – Servo controlled voltage stabilizer adjustable between 200 to 240V at 10A max. regulation ±1% - 3 Nos

2. Yokogawa make power meter (3 Phase) to indicate the parameters such as voltage, current, wattage, power factor and energy). This will be interfaced with PC for monitoring the readings – 1 No

3. Temperature datalogger/ Scanner (Keysight make) with 20 Channels temperature sensors (2 modules). This will be integrated to PC through Ethernet connectivity

4. PC will be HP or Dell or Lenovo make with Windows 10 OS, 18” monitor, Keyboard and mouse

5. Testware (Application Software) - LabVIEW based for controlling the sequence of operation, datalogging and generating reports. This software is very much user friendly and easy to operate. The graphical UI for each test makes it easy to operate for unskilled labourers while the advance report generation modules enables for analytics

6. Time measurement will be through PC

7. Temperature Sensors, PT 100 with fixing nuts

8. Cookware and cookware lid with accessories for sensor fixing of all each size as mentioned in standard – 8 Nos

9. Precision Weighing balance - 5 kg, 1 gm resolution. with PC connectivity

10. Chiller with temperature control to maintain water temperature between (10°C to 20°C)

11. Test Chamber (Size : 1.5 meter X 2 meter X 2 meter) – Constructed with aluminum sections and front side door open with safety interlocks and exhaust facility

12. Air conditioner (15°C to 25°C) for test chamber size- 1.5 meter X 2 meter X 2 meter

13. Control unit constructed with extruded aluminium section. This houses all the electrical /electronic component, PC with monitor, keyboard and mouse

14. PLC or Specially designed SCR make DAQ for interfacing

15. Air flow meter (0.5 m/s)

16. Air Pressure Transducer to measure 0 to 1.5 Bar

17. Set of Contactors, relays and MCB’s etc

18. Weighing scale with direct interface with to measure weight of water

19. 1 set of Standardized cookware (as mentioned in 5.6.1.5)