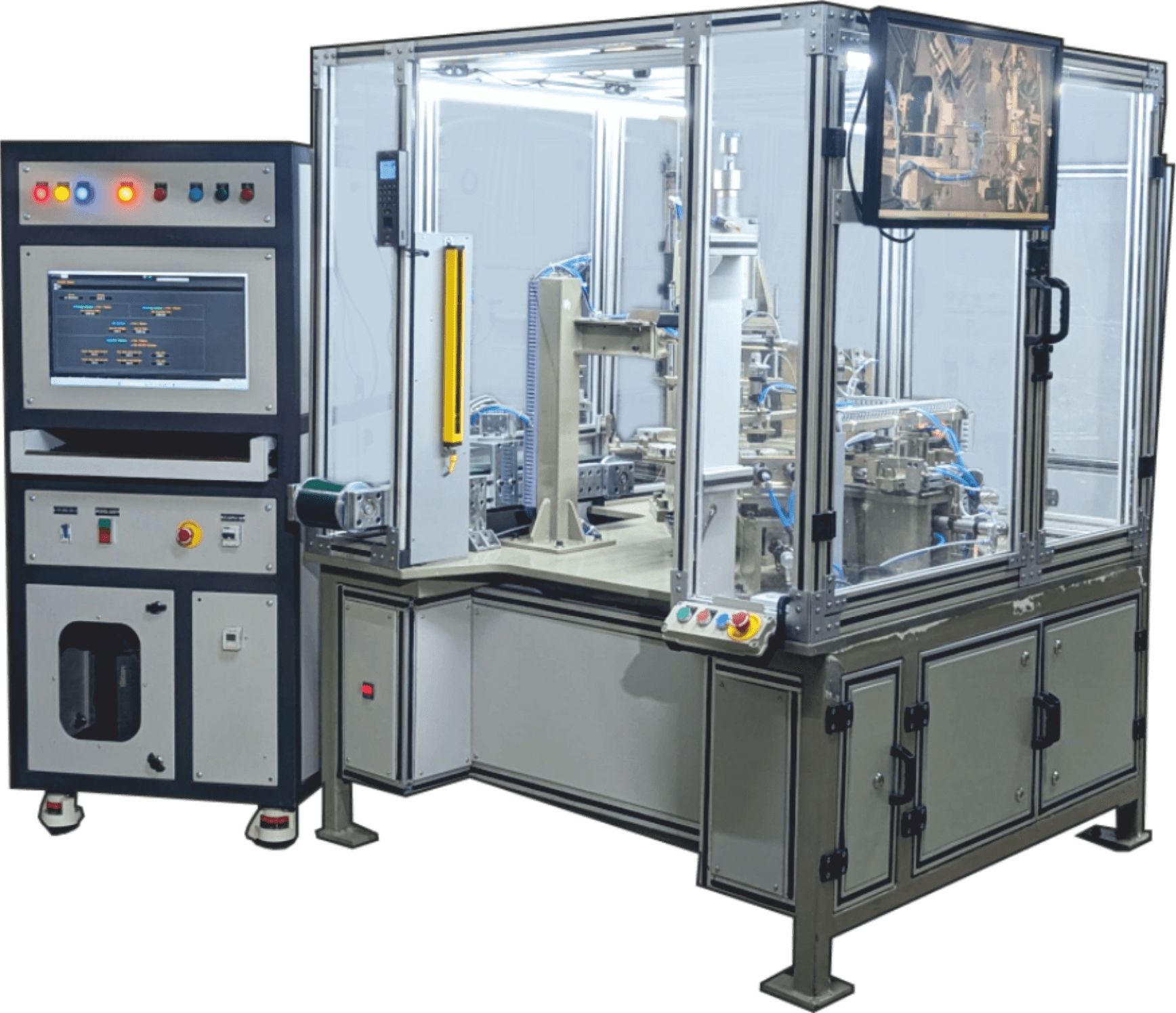

Innovative machine from SCR Elektroniks enhances MCB production efficiency, featuring automated testing and riveting processes, integrated safety checks and complete automation enabling single operator management while ensuring quality and compliance with IEC60898 and IS 8828 standards

This Test Bench is designed to automatically do Riveting of MCB after performing following Test's (Arch Chute Detection, Continuity, Magnetic Hold Test, Magnetic Trip Test, High Voltage Test). It has Indexing/Turn Table which has total 8 Station's and it can give output of 1 MCB per 6 Seconds