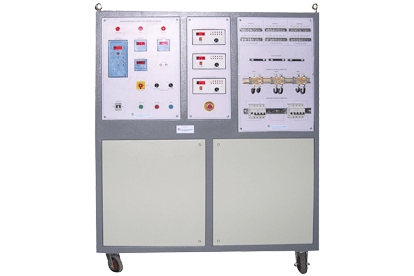

The SCR Elektroniks 12 station MCB Tripping Characteristics Test Bench is optimally designed to verify the Tripping Characteristic of MCBs as per clause 9.10.1 of IEC 60898 (Also mentioned in Indian Standards IS 8828). The bench essentially comprises of Servo Controlled mechanism to set and maintain desired current (against incoming mains fluctuation) and a Micro controller based master controller unit plus timer, which governs the entire sequence of operation making it a stand-alone system once the user connects the MCB and configures the test parameters.

This test equipment also covers testing as per Indian Standard IS 8828 as well as Indonesian Standard SNI 8528-1 (BSN)

Completely stand-alone unit after initial configuration of test parameters

MCB Range Selection : Through neatly labelled shorting links

Chart provided on the panel for using the right CT links and Voltage Taps for required test currents (1.13 In and 1.45 In

Instantaneous Bypass arrangement on each station in the event of MCB trip to maintain uninterrupted current

Arrangement to connect lugs of various sizes inside the heating chamber

Individual test time measurement for each station

Graded inductors to maintain required OCV at the source output (Min 30 V as per standard) especially while testing less number of MCBs

Change of test current (from 1.13 In to 1.45 In) after set time (usually 1 hour) is automatic.

The user may simultaneously test MCBs of different brands and compare the test results (Ideal Application for Test Labs and Certification Agencies).

PC Based Option Available (Extra) for control and data keeping on a PC (SCADA) with customized software

User friendly digital interface to input test parameters

2.55 test on reduced number of stations by user setting

Input Supply : 230 V +/ - 10%, 35 Amps AC, 50 / 60 Hz (o/p frequency same as i/p frequency)

Twelve samples can be tested for No Trip /Trip Test simultaneously (6 samples on 6 station bench)

Mode of Operation: Manual Mode and Auto Mode

Output Current : 0.5 A to 145 A

Heating chamber of size 1200 mm, 1000 mm, 300 mm (approximate: different for 6 stations) provided with bus bar to accommodate lugs of different sizes for each station with precise temperature controller (programmed from front panel) to maintain temperature +/- 2°C (Range: 30°C to 60°C)

Ratings of MCBs covered : 0.5A, 1A, 1.6A, 2A, 3A, 4A, 6A, 8A, 10A, 13A, 16A, 20A, 25A, 32A, 40A, 45A, 50A, 63A, 80A, 100A (Max rating of MCB can be customized such as 32, 63, 100 A)

Available test stations on the panel : 6 or 12 stations

The product can be customized as per the MCB range desired by the user, in addition, the user may opt for number of stations, whether the bench is with an integrated oven or not. Plus, PC based option is provided for automatic operation. Some MCB manufacturers opt to club the temperature rise test with the tester so as to measure the temperature of the internal parts of the MCB when subjected to testing inside a temperature chamber.

The tester is used to carry out the 1.13 and 1.45 test, optionally inside a heated environment (temperature chamber). As more breakers are tested simultaneously, the user may compare the quality of MCBs of several brands and arrive at a report.