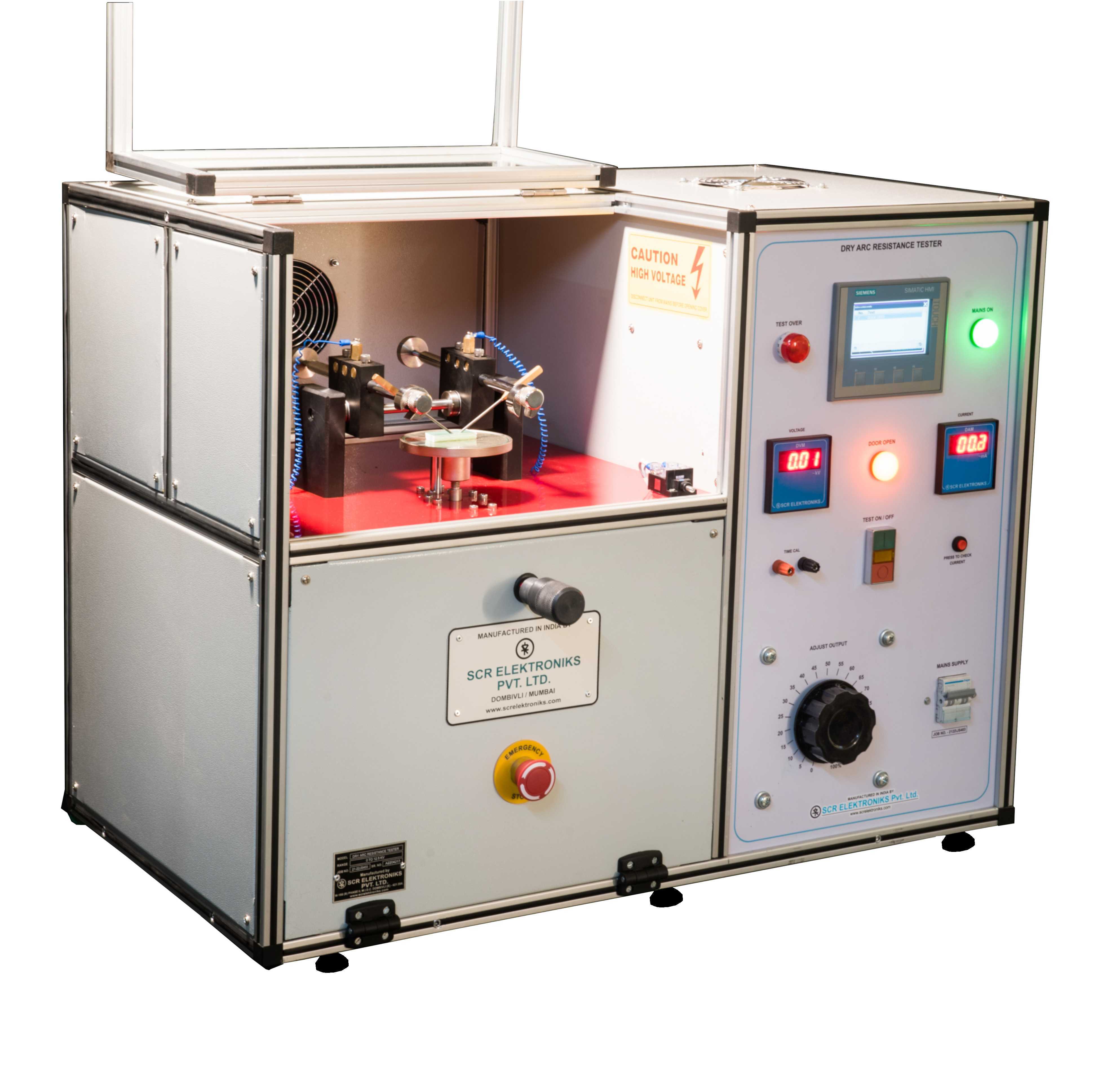

This equipment is made to test the electrical insulating material by exposing it to Arcing under high voltage. The test specimen is placed under electrodes, spaced at a distance of 6.35mm as per ASTM D 495. An Arc is generated between these electrodes. The test consists of 7 Cycles starting from cycle 1. As the cycles progress the test becomes progressively severe. The test specimen that has lower insulating strength fails earlier in the first few cycles while those with higher insulating strength sustain higher cycles. The test is halted when the specimen fails and the time taken from the start of the test till the failure is used for comparing INSULATING STRENGHTS (time in seconds) of various insulating materials. The test specimen may fail by forming a conducting path, by burning into flames, by melting or any other physical, visual deformities.

The test method as per ‘ASTM D 495 – Standard Test Method for High-voltage, Low-current Dry Arc Resistance of Solid Insulating Material’ is pre-programmed in the PLC. Please refer to ASTM D 495 for more details. This equipment complies testing as per other standards as well, such as IEC 61621 (Dry, solid insulating materials - Resistance test to high-voltage, low-current arc discharges), UL 746 A (Polymeric Materials – Short Term Property Evaluations Testing For Electrical Properties) and IS 14672 (Method of Test for High Voltage Low Current Dry Arc Resistance of Solid Electrical Insulation).